Huge Cost Saving via 94% Reduction in Plate Usage

The Challenge: Annex 1 Compliance in a Grade A Environment

This customer specialises in water hygiene and infection prevention. It’s a global organisation, and this particular location happens to be in the UK.

The Senior Microbiologist was working on a project to make sure that the Grade A facilities at this particular site would be ready for Annex 1, and fully compliant. She was faced with two major challenges:

- Lack of Biological Efficiency.

The site had been using an alternative technology for many years. However, this technology did not have the required biological efficiency to be Annex 1 compliant.

- Rapid Consumption of Agar Plates. In addition, having made the decision to perform continuous monitoring in Grade A areas, the customer found themselves changing agar plates every 10 minutes and generating 36 plates per shift for each of their sample locations.

What to do? In early 2020, the customer began to talk to us.

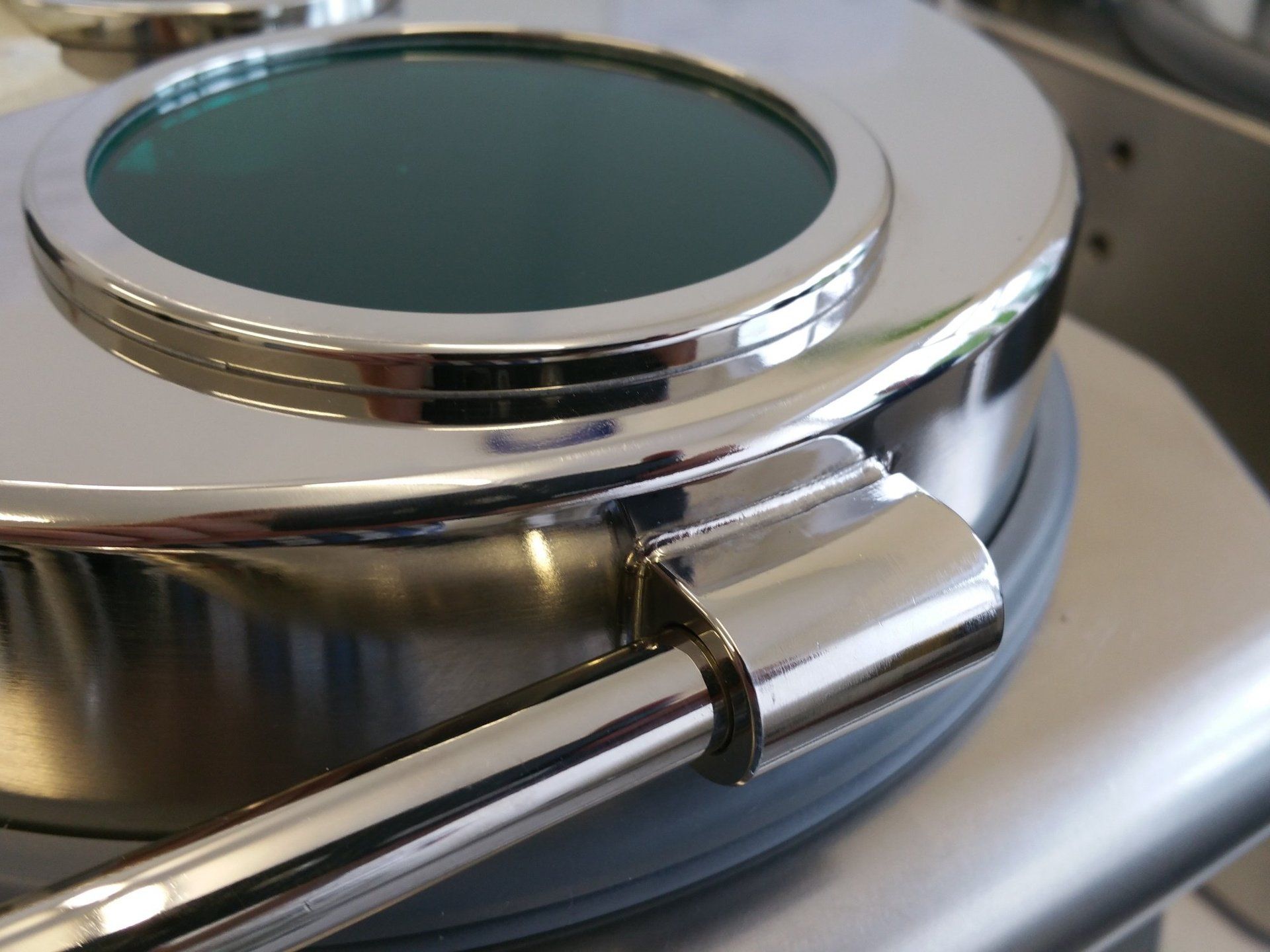

The Solution: The CAMS ISO-CON-90 Complete Monitoring System

We discussed how we would address the challenge. Working with the customer and our distribution partner, PMT, we established that a solution based on the CAMS ISO-CON-90 Complete Monitoring System would meet all of the customer’s requirements.

We had recently released the ISO-CON-90 Complete Monitoring System as the latest addition to the CAMS range.

Biological Efficiency

This proved to be the perfect solution. The customer ordered two ISO-CON-90’s. These devices were quickly in action, and demonstrated the required biological efficiency to meet Annex 1.

Agar Plate Use

The other great advantage was in reduced consumption of agar plates. The team had expected a significant reduction - maybe 70%. However, the actual results achieved have delighted everybody.

The time between plate changes has increased from ten minutes to four hours! This means that the rate of plate usage has dropped from 36 per location per shift to 2 per location per shift – a reduction and associated cost saving of 94%.

Fantastic Return on Investment

A 94% reduction in any expense is going to represent a significant saving. We respect the commercial confidence of this client, and so we will not publish actual figures. However, to give you a feel for what you might be able to achieve, let's look at a worked example which shows a typical return on investment that a project like this might represent.

A reduction from 36 plates per shift per location to 2 plates per shift per location is a reduction of 34 plates per shift, per location. At volume, the typical price of a plate might be 75p. So the cost saving is 34 x 75p, or £25.50 per shift per location. In this case, there are two locations, so £51.00 per shift saved.

Let's be conservative and assume the operation is two shifts, five days per week, and monitoring does not take place outside these shifts. Let's also assume that four weeks per year are lost to holidays and maintenance. So, the site in our example operates 2 shifts x 5 days per week x 48 weeks per year = 480 shifts per year. A saving of £51.00 per shift gives an annual saving of £24,480.

This means that on this basis alone, using these very conservative figures, the two ISO-CON-90's would pay for themselves in approximately nine months, and then go on to save the customer a further £6,000 (approximately) in the first year alone.

In the second year, and in subsequent years, all other things being equal, the saving per annum would be the full £24,480.

In practice, many operations run more than five days per week, or more than two shifts, or more than 48 weeks in a year, so the savings would be greater and the ROI quicker.

This is on the basis of plate savings alone. There are also savings in time spent changing and reading plates, waste disposal, and stock holding, not to mention the environmental benefit, reduced biohazard, etc.

Local and Global

The system has been in place now since the spring of 2020, and continues to deliver Annex 1 compliant continuous monitoring and cost savings when compared to its predecessor every day.

We’ve had expressions of interest in the ISO-CON-90 from around the globe, so we didn’t expect our first sale of the system to be to a customer with a facility only a few miles down the road from our head office in Wales – but that’s exactly what happened!

Start Now

Find out more about Annex 1 compliant continuous monitoring with CAMS solutions, and how you might be able to save on your use of prepared media.

1st floor (SMF), North Road, Bridgend Industrial Estate, Bridgend, UK, CF31 3TP

© Clean Air Monitoring Solutions 2025. Cedwir Pob Hawl / All Rights Reserved.