ISO-90 - Monitoring Head

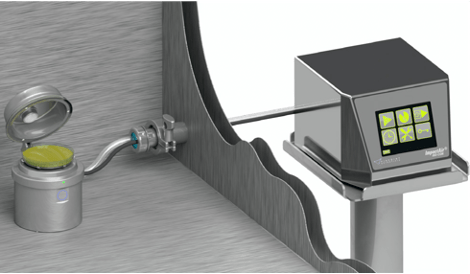

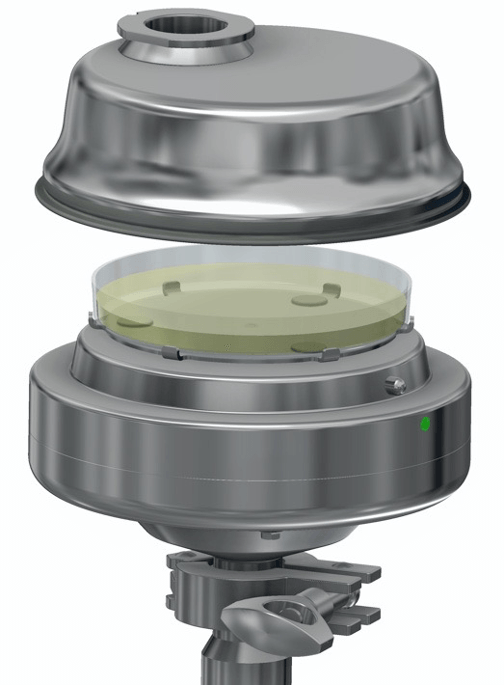

At the heart of this flexible new platform is the new ISO-90 monitoring head. The head contains all controls and mechanisms necessary to rotate the agar plate throughout the monitoring period. The head does not contain a pump but internal flow sensors are used to enable the head to send signals to a vacuum source to control the air flow very accurately.

The head is 122mm diameter and 107mm from the clamp flange to the top of the inlet.

There are a number of different approaches using active air samplers to meet Annex 1 compliance. The pharmaceutical industry uses isolators, R.A.B.S., and others manufacture in cleanrooms. Some processes are highly automated and some more manual. Users also require flexibility to monitor for shorter periods at higher efficiency, whilst others want to monitor for the longest period possible with minimal human intervention.

These different requirements would normally necessitate different instruments but the ISO-90 head inlet can be configured to optimise the sampling parameters. There is a default configuration that allows 4 hours monitoring onto a single agar plate with a flow rate of 15 litres per minute at a d50 of 0.53μ.

Alternative inlet sizes are available.

A button located on the head unit is available so the operator can simply load a plate and press the button to start, pause or stop a run.

The head can be supplied in a number of deployment formats to suit the application and with an increase in the use of robots within isolators, the chamber can also be supplied with robot compatible manipulation features.

History

Most users are already familiar with using agar based methods for environmental monitoring - using settle plates for up to 4 hours and air samplers to sample a cubic metre of air in just 10 minutes. Along with these methods, users will have many years of valuable experience of handling plates, interpreting the results and a wealth of historic data as a reference.

Early air samplers typically used larger agar plates and were capable of sampling for longer periods, but with legislation allowing the use of ‘rapid m3 samplers’, the need to monitor disappeared and agar became a forgotten monitoring method. The introduction of Annex 1 has left many in the industry searching for a suitable monitoring technology. Real time fluorescence based systems are pitched as the ‘latest and greatest’ solution but they are complex, results interpretation is not as clearly defined as agar based methods and crucially, they do not allow easy identification to species level.

The most effective way to achieve Annex 1 compliance could be to stay with your existing proven, trusted and validated agar based methods. In most cases there is no need to change to a different technology at all. Agar is easy to use and easy to understand. It works perfectly well, why change?

By simply changing from an air sampler to an air monitor, 4+ hours continuous monitoring is possible using a single 9cm agar plate and CAMS has developed a range of monitors to achieve just that.

The CAMS Difference

CAMS air monitors are based on the slit-to-agar method which has very low d50 values of around 0.5μ with exceptional biological efficiency and the ability to easily count real viable microbial events in CFU while being able to identify to species level using existing methods and existing historic data as a reference.

CAMS has listened to the voice of many end users and created a monitoring platform that meets the requirements of the regulations whilst offering a range of flexible solutions to meet the end users specific requirements. The platform uses common components and user interface throughout to create a suite of solutions based on the same core technology that can be deployed across all areas. Using a common platform reduces the operator training requirement, reduces risk, simplifies regulator audits, simplifies product support and calibration, and allows data from different areas to be compared on the same baseline.

CAMS also supplies a vacuum pump solution (ISO-CON) but it also has the flexibility to allow isolator manufacturers to connect the ISO-90 head into an existing vacuum system and perform their own control

All CAMS monitors are built using 316L stainless steel.

Technology

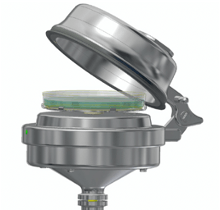

Air is drawn at high speed through a very narrow inlet slit, whereupon particles, including microbes in the air, impact and stick onto an agar surface in a petri dish. The petri dish is slowly rotated under the inlet, thus ensuring the air is always ‘impacted’ onto an area of fresh agar. This dramatically reduces the desiccation of the microbes resulting in a very high biological and physical efficiency unmatched by other types of sampler or real-time systems.

Another advantage of the rotating agar plate is that the results are time correlated. Whilst not timed to the second, localised growth on the plate can be time estimated based by its position on the plate.

Specification (Default Settings)

| Air flow | 15 lpm | Communication | USB, Ethernet |

|---|---|---|---|

| d50 | 0.53μ | Certification | CE |

| Plate size | 9cm | Interface | MODBUS/SCADA |

| Sampling time | 10 min to 4 hours | Weight | Model dependent |

| Plate usage | 1% to 100% | Head Ø | 122mm |

| User interface | Touch screen LCD | VHP | Head VHP compatible |

| Exhaust | HEPA H14 | Noise level | 65dB Max |

| Construction | 316L Stainless | Validation | Physical & Biological |

| Inlet | F22 Fitting | ||

| Power | Universal PSU |

Download the ImpactAir Product Guide

Contact us about ImpactAir-90 and ISO-90

1st floor (SMF), North Road, Bridgend Industrial Estate, Bridgend, UK, CF31 3TP

© Clean Air Monitoring Solutions 2025. Cedwir Pob Hawl / All Rights Reserved.